Contents

1. Introduction

2. General

- 2.1. Which dams need an operations and maintenance plan?

- 2.2. What is an operations and maintenance plan?

- 2.3. Preparing the plan

- 2.3.1. Specialist involvement

- 2.3.2. Industry precedent and best practice

3. Dams safety regulation 2019

- 3.1. Regulation clause 9

- 3.2. Related clauses of the regulation

- 3.3. Dams Safety NSW role in auditing operations and maintenance plans

4. Plan form and contents

5. References and useful resources

Appendix 1 The dam safety management system risk framework and operations and maintenance plans

- Applying the risk management framework to operations and maintenance

- General

- Failure modes analysis (FMA)

- How surveillance activities relate to the FMA process and review of the plan(s)

- Other risk-based approaches

Appendix 2 Maintenance planning for a simple dam

Print-friendly PDF (PDF, 779.12 KB)

1 Introduction

Dams Safety NSW is an independent regulator established under the Dams Safety Act 2015 (the Act). Dams Safety NSW seeks to ensure that dam owners achieve compliance with the Act and the Dams Safety Regulation 2019 (the regulation).

Dams Safety NSW ‘declares’ those dams which have a potential to threaten downstream life, or cause major property, environmental, or public welfare damage. Owners of declared dams must comply with the requirements of the Act and regulation.

Dams Safety NSW publishes guidelines to clarify legislative requirements and to provide information to assist dam owners.

This guideline is not a legislative document; dam owners are not required to adopt the suggested methods, techniques or other material contained in it and a dam owner may adopt other approaches if they fit better with a dam owner’s systems.

Dam owners are responsible for ensuring compliance with the legislation and this guideline is not intended to provide an acceptable means of compliance.

When referring to the requirements of the legislation the guideline uses the words ‘need to’, ‘required to’, ‘requires’ or ‘must’. Otherwise, it uses the words ‘may’ or ‘should’ when clarifying requirements or suggesting actions, methods or techniques.

The purpose of this document is to provide dam owners and their consultants with guidance when they are developing or reviewing the operations and maintenance plan(1) for a declared dam.

For the dam owner, an effective plan is focussed on the continued safety of the dam and its appurtenant structures, minimises the risk of dam failure due to poor operation and maintenance, maximises uninterrupted service, minimises costly repairs and extends the useful life of the dam. Improper operation of a dam may result in dam failure, and poor maintenance can lead to abnormal deterioration of the dam and its components, reduced life expectancy and increases the likelihood of dam failure.

An effective plan will also ensure that adequate information is available to the dam operator/owner, their consultants and contractors, the regulator and, where appropriate, other stakeholders such as the downstream community, emergency services and insurance organisations. This will validate that the dam is being operated and maintained in a safe manner.

All declared dam owners must implement appropriate operations and maintenance plans to ensure the ongoing safety of their dams and to comply with the requirements specified in the regulation. A copy of the Dams Safety Regulation 2019 can be downloaded from the NSW legislation website: https://legislation.nsw.gov.au/.

A dam owner may satisfy the legislative requirement through the documentation of a plan or a set of documents that achieve the same purpose. For example, a dam owner may have a separate operations plan and a separate maintenance plan. Some dam owners may have an integrated maintenance system that embodies many of the facets of an ‘operations and maintenance plan’, which is also an acceptable way of documenting parts of the ‘plan’.

This guideline has been based on the dams safety legislation, the AS ISO 55001:2014 asset management systems standard and with consideration of ANCOLD2 (2003a) and other references that are cited in the text.

The plan should be documented so that it can be easily understood and followed by all involved in the operation and maintenance of the declared dam.

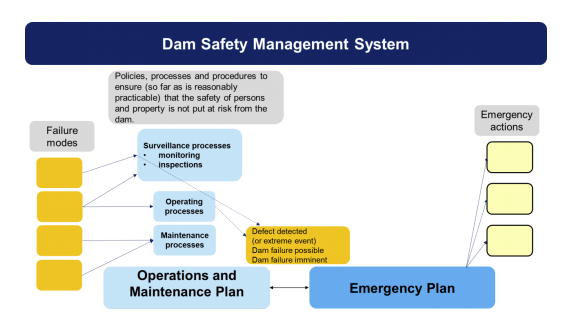

The plan forms part of the dam safety management system. Figure 1 depicts the relationship between the safety management system, the operations and maintenance plan and the emergency plan for the declared dam.

2 General

2.1 Which dams need an operations and maintenance plan?

All declared dams are required to have an operations and maintenance plan.

The operations and maintenance plan should be tailored to the type, size and complexity of the dam. Declared dam owners need to determine the plan’s level of detail and complexity accordingly.

An operations and maintenance plan for a simple dam structure with a low or very low consequence category may be a comparatively simple document, whereas one for a large, complex dam should be more comprehensive to reflect the complexities of the dam and its operation and maintenance.

2.2 What is an operations and maintenance plan?

Many owners of declared dams in NSW will already have an operations and maintenance manual for their dams.

To prepare the dam’s operations and maintenance manuals most dam owners are likely to have used guidance material such as the ANCOLD (2003a) guidelines and additional information from other guidance sources referenced in that guideline. The dam owner may document the topics and sections within an operations and maintenance plan (however named) in any way that fits with their overall system documentation and the ‘traditional’ layout of an operations and maintenance manual may be retained, with appropriate additions to reflect the requirements of the regulation. Section 4 describes one way to lay out an operations and maintenance plan.

An operation and maintenance plan is essentially a similar set of controlled documents to an operations and maintenance manual. However, a plan should also have regard to the following additional aspects:

- the plan forms part of the dam safety management system. It should be prepared in accordance with the operations and maintenance clause of the regulation and also with regard to other relevant clauses of the regulation. For example, a plan should:

- include procedures for managing risks (e.g. surveillance inspection activities address deterioration risks and detect the development of problems or unsafe trends)

- cater for resources to be applied (clause 13)

- apply the risk management framework (clauses 14 and 15) to validate operating and maintenance procedures which deal with potential failure modes, emergency(3) action and incident reporting, and monitoring and surveillance

- include the processes for maintenance planning, work allocation and recording of maintenance tasks

- include the processes and procedures to achieve compliance with clause 9 of the regulation (refer to Section 3).

- interface with (or cross-reference) the emergency plan3 . For example, provide for:

- attendance and communications procedures associated with emergency planning including inspections and monitoring, implementation of warning systems/alarms

- whether a qualified/experienced observer should be in attendance at the dam when flood conditions, or signs of serious structural distress have been identified

- inspection and advice by an experienced dam safety engineer (competent person) (4) in the event of a potential dam safety incident

- extreme and emergency operations-related items (e.g. instrumentation, alert triggers, warning alarms etc.) and

- a reference to where owner and emergency services organisation staff contact lists and authorisations are located

- include procedures for detecting, reporting and preventing or mitigating incidents in accordance with clause 19 of the regulation

- incorporate updates to design operating criteria, failure modes or other recommendations that may affect operations and maintenance arising from a safety review, or related dam safety investigation (clause 20).

Owners of declared dams who already have an operations and maintenance manual should review and update the documentation to ensure that it satisfies the requirements of the regulation.

2.3 Preparing the plan

The plan should be tailored to the type, size and complexity of the dam and its associated structures and flow control components.

When developing the plan, a dam owner should consider issues which may affect complexity including but not limited to:

- size of the organisation

- the complexity of dam operations – for example, detailed operating procedures will be required for a dam with a spillway which is controlled by large, high capacity gates which could release damaging flood flows downstream

- degree of backup required

- complexity of spillway arrangements

- simplicity of flow regimes

- complexity of outlet works structures (civil) and associated flow control equipment (mechanical and electrical)

- location of the dam and

- distribution of responsibilities between maintenance and operating personnel.

2.3.1 Specialist involvement

The regulation provides a definition of a competent person(5) and stipulates that the person needs to carry out activities specified in clauses 7 (assessment of consequence category), 20 (safety review) and 24 (review work involving design).

The dam safety management system, through AS ISO 55001:2014, requires the dam owner to determine the resources and competencies needed to establish, implement, maintain and continuously improve the dam safety management system and its associated procedures and documentation. This includes competencies for the preparation and implementation of the plan.

Therefore for existing dams, depending on the dam consequence category and complexity of the dam, it is recommended that professional dams engineers (civil, structural and mechanical and electrical engineers) and other relevant specialties(6) be involved in the preparation and review of operations and maintenance plans (following their involvement in the regulation clause 15 risk report development). If not involved in detailed plan preparation, the advice of a competent person should be sought.

The designer of a new dam or upgraded dam should be involved in the preparation of and/or review of the plan.

The engineering specialists would be able to prepare maintenance checklists and schedules indicating the maintenance procedures, frequencies and protective measures for each structure and for each piece of operating, communications, and power equipment, including monitoring systems. Mechanical and electrical equipment manufacturers will be able to provide supplementary inputs typically including technical data sheets, drawings, operating, maintenance (preventive and corrective) and servicing instructions, test certificates, discharge ratings (valves etc.).

Professional engineers specialising in the design and condition assessment of mechanical and electrical equipment for major dams are especially important resources when preparing a plan involving gates, large valves and other complex mechanical and flow control equipment (e.g. the operation, maintenance and replacement of valves and motors for gates).

2.3.2 Industry precedent and best practice

It is noted that most of the procedures for operations, maintenance and surveillance(7) have traditionally been established based on industry precedent, good practice and similar generic examples. This process is reasonable because the causes and processes of dam failure are varied, and the knowledge gained from dam incidents and (less frequent) dam failures contributes to the knowledge essential to the prevention of future failures.

It is important to include, but also think beyond, the traditional standards-based analyses when identifying potential failure modes as they relate to operations and maintenance. The application of failure modes analysis, or other forms of risk assessment, enhances and tailors the operations and maintenance activities specific to the dam.

Appendix 1 discusses how the dam safety management system failure mode analysis process relates to operations and maintenance.

3 Dams safety regulation 2019

3.1 Regulation clause 9

Clause 9 of the regulation sets out specific requirements that must be addressed in operations and maintenance plans.

A dam owner must prepare and implement an operations and maintenance plan to meet the regulatory requirements.

Section 3.4 provides guidance for dam owners to assist with addressing section 9 of the regulation.

3.2 Related clauses of the regulation

Section 3.4 also provides guidance for dam owners to assist with addressing other related clauses of the regulation. Examples include roles and responsibilities, and training and competency requirements for operations and maintenance.

3.3 Dams Safety NSW role in auditing operations and maintenance plans

Dams Safety NSW will visit declared dam owners during the regulation transition period to determine how dam owners have prepared and implemented operations and maintenance plans and to support dam owners in understanding what they need to do to comply with the regulation.

After November 2021, Dam Safety NSW will implement a risk-based audit programme which will include management system audits of dam owners’ systems, including operations and maintenance plans, to determine compliance with the regulation.

3.4 Guidance on addressing the requirements of clause 9 of the regulation

Clause 9 (1)(a) - the operating procedures for the dam with a concise description of the procedures and limits (operator controls) of plant and equipment used in the operation of the dam

Operating procedures

Dam owners are required to operate the dam within a range of design operating criteria under normal, abnormal and extreme load conditions. These criteria may need to be updated from time to time as a result of a safety review(8) or other dam safety/design investigation (e.g. flood study), or because an existing dam is modified. The dam is operated and maintained so it performs within the established criteria.

The dam design operating criteria and data should be included in the plan so that all operation (and maintenance) information is included in one (controlled) document. This data is usually obtained from the design report and/or design summaries.

Operating procedures usually incorporate the following four levels of documentation:

- basic data that supplements the procedures (e.g. description of elements, spillway type and capacity, supply operating levels)

- operating procedures(9) – fundamental protocols and responsibilities for operating a system in the dam or carrying out tasks critical to dam safety; e.g. activation of alarms, spillway operation, water releases by gate/valve, penstock dewatering, dam safety incident reporting)

- detailed (step-by-step) instructions that address how to operate systems and individual pieces of equipment (e.g. operation of control valves).

- supporting documents and reference material (e.g., dam safety management system, emergency plan, design operating criteria, work-as-executed (as-built) drawings, equipment manufacturers’ instructions and drawings).

All the above operational documentation (however organised or named) should be incorporated in, or referenced from, the plan.

Procedures need to be documented to enable the safe operation of the dam under normal, abnormal and extreme loading conditions (clause 9 (2a)). The procedures may need to include aspects unrelated to the dam itself; e.g. coordination of releases with other dams (e.g. for cascade of dams), communications with NSW SES and other agencies and activation of flood warning to downstream areas.

The procedures, instructions and documentation should be clear-cut, such that persons unfamiliar with conditions at the dam can comprehend the instructions in an extreme event. Cross-refencing to other parts of the plan, emergency plan, dam safety management system, and to supporting data including drawings should be provided with all information at hand.

Sequencing steps should set out clearly the safe operation of flow control equipment, along with sketches, drawings and photographs to aid in identifying specific buttons, levers etc. Provision and usage of backup equipment should be outlined. For mechanical equipment, provide context (purpose/function), describe and outline the operating and maintenance procedures. Electrical operations and maintenance requirements may be incorporated under the main operational element (e.g. intake tower electrics) with any special notes added as a sub-section under the specific mechanical equipment item (e.g. sequence of operation of overhead crane). Special sections relating to electrical requirements are also usually included (e.g. power supply and distribution).

The means of communicating both in normal, abnormal and extreme conditions (e.g. during a flood event) should be identified with appropriate cross-referencing to the communication/notification directory provided in the emergency plan.

The individuals, operating unit and organisations responsible for and extent and frequency of attendance at the dam should be identified in the plan.

Details relating to the remote operation of mechanical equipment (gates and valves) should be provided along with any associated safety precautions.

Special procedures and sequencing steps required to operate, inspect and maintain mechanical equipment should also be documented. Special procedures may be afforded its own sub-section for clarity purposes and may be contained in operating or maintenance sections of the plan as appropriate. Examples of special procedures include:

- isolating valves and pipelines, creating ‘no flow, balanced head conditions’ and dewatering and recharging outlet conduit(s)

- discharging water through valves

- operational testing of selected intake/outlet equipment

- work, health and safety provisions (e.g. safety harnesses, mobile lifts, fall arrestors, temporary handrails, lifting slings, physical locking and tagging out of equipment, wind speed checks, trained employees only etc.)

- internal inspection of valves and pipelines

- entering outlet works valve pit(s) and associated fall prevention and confined space procedures

- manoeuvring, installation and removal of trash screens/baulks and bulkhead gates from guide slots.

Note: special procedures are typically carried out prior to initiating maintenance activities of mechanical flow control items; e.g. sequencing steps to install a bulkhead gate in the intake tower base and to dewater the penstock are required before an inspection of a conduit can be undertaken. The last four examples in the list relate to maintenance special procedures (ie are not specifically operating procedures).

Depending on the size and complexity of the dam, maintaining an operations log, which provides a chronological record of important events relating to operations and maintenance and dam safety, should be considered. The log should cover all dam components including civil works, mechanical equipment and electrical equipment. The log may be helpful in providing clues to the cause of equipment failure and the development of unusual conditions.

Further guidance regarding operating procedures and instructions can be found in DNRM (2002) and ANCOLD (2003a).

Clause 9 (1)(b) - details of each circumstance in which an alarm will be triggered in respect of the dam and the response and reporting protocols that will occur when that alarm is triggered

Alarm states and response, notification and reporting protocols are associated with:

- emergency alarm levels, response and notification; i.e. as identified in the emergency management plan

- triggering of electronic or telecommunicated flood warning systems as part of an emergency response (if applicable)

- operation of mechanical and electrical flow control systems (cranage, valve and gate operation, flow measurement etc.)

- SCADA/telemetered dam safety instrumentation trigger alerts (storage level, seepage flowrates, piezometric pressures etc.)

- manually-read dam safety monitoring data not catered by electrical systems (e.g. seepage weir discharge) The individuals, operating unit and organisations responsible for dealing with responses and level of attendance at the dam should be identified in the plan.

The emergency plan is the principal document for detailing emergency alert levels. However, the plan should cross-reference the emergency plan and may also include a summary of communications flow charts and emergency contact numbers (although care should be taken that these are updated in line with the emergency plan contacts). The means of communicating both in normal and emergency (e.g. during a flood event) should be identified with appropriate cross-referencing to the directory provided in the emergency plan.

The plan needs to set out the roles and responsibilities of, and actions required by operational staff and consultants/contractors; i.e. to ensure the emergency action plan and any associated operational checks, inspections and corrective maintenance or remedial works are triggered during and after such events (flood, seismic or sunny day piping event). There may be other overlap in the operations and maintenance and emergency plans (e.g. describing access the dam site during a flood event). Since both plans are controlled documents, duplication of information should be avoided where possible. Regardless, they should be updated together. Maintaining consistency across the plans and the overarching dam safety management system is important and should be attended to regularly.

Surveillance activity, including inspections and the processing and evaluation of monitoring data may detect abnormal behaviour which in turn should trigger a response to determine if it indicates a worsening dam safety situation. Inspection frequencies should be increased (for example inspections at the start of each employee shift if employees are at risk of a dam failure) if monitoring shows an increased risk to the dam.

Dam owners should ensure that the system, processes and personnel used to collect, and assess monitoring data have the capability to detect errors, instrumentation malfunction and actual abnormal behaviour of the dam. Such abnormalities can be a trigger for more intensive surveillance or remedial action. Back-up manual surveillance by operations personnel may need to be intensified if such systems are down or unreliable.

Note: For very simple dams, alarms may not involve sophisticated equipment and may be described in the emergency plan.

Clause 9 (1)(c) - the maintenance (comprising corrective and preventive) that will be carried out on the dam, the times at which that maintenance will be carried out and who is responsible for the maintenance

Maintenance management

The plan should describe how maintenance and routine surveillance is planned and organised. This includes how the maintenance and inspection schedule is prepared (resulting from the risk assessment and maintenance planning process), and the work assignment and work recording process.

Maintenance schedules should be prepared that detail the dam element, description of task, frequency of maintenance and special requirements for servicing and maintaining the equipment (including equipment manufacturers’ recommendations). The maintenance schedule should be a calendar-based schedule assigning specific dates to the tasks identified in the maintenance planning document, the required repair tasks identified by inspections and any capital works that have been identified by the strategic analysis of the dam risks.

For larger dams the maintenance schedule, activities and tasks, and subsequent reporting, is usually held in a maintenance management system that allows scheduling and issuing of work instructions, recording of findings, outputs and outcomes and the ability to extract data for analysis and planning purposes.

For smaller, non-complex dams, the maintenance schedule is likely to be based on a simple calendar planning system (manual or electronic). Similarly, the work assignment and recording system that issues and tracks work issued to operational staff and others may also be relatively simple.

Maintenance types

Maintenance can be described as preventive, corrective or emergency.

Preventive maintenance can be either routine (time-based operations) or condition-based (reliability-based, improvements, non-critical repairs and upgrade works). The preventive maintenance schedule should be derived by addressing the risks identified in the risk assessment process that are managed by preventive maintenance.

Routine maintenance typically makes up most of the maintenance schedule with tasks such as dam surveillance and monitoring, mowing the embankment face, operating and lubricating gates, annual testing of critical flow control equipment, cleaning pressure relief drains, operating scour outlets to keep free of silt, testing of monitoring equipment and replacement of consumable items.

Condition-based maintenance should be identified, scheduled in the owner’s maintenance system and budgeted for annually. Examples include repairing surface defects in spillway concrete, clearing vegetation and trees from embankments and outlets, replacing degraded rip rap, embankment crest road pavement repairs, servicing or replacing gates and valves, painting steel work, corrosion protection of steel conduits.

Corrective maintenance is carried out when immediate remedial action is required to cover the unforeseeable repair of assets that have suddenly deteriorated, on the verge of, or have failed. Emergency maintenance falls under this category and includes immediate remedial responses to prevent failure of the dam or part of the dam system. Examples include excessive seepage initiating piping, embankment slope instability, major flood or earthquake damage, blockage of retarding basin outlet, inoperable spillway.

Refer to guidance under clause 9(1a) regarding special procedures which may apply to maintenance (e.g. bulkhead gate installed in intake tower base caters for isolating the outlet penstock from the storage, allowing for inspection and maintenance).

Equipment data sheets or manufacturers’ manuals are typically appended to the mechanical and electrical section of the plan to facilitate maintenance, repair and overhauling of mechanical and electrical equipment. For example, an equipment data sheet or manufacturer’s manual should exist for the operation, maintenance, repair and overhaul for the emergency generating set.

Maintenance procedures

The plan should document the responsibilities, processes and procedures for maintaining the dam, including:

- roles and responsibilities for maintenance

- maintenance tasks required to be achieved

- procedures for maintenance which are clear and concise, with diagrams and photographs as required

- work instructions that describe the step-by-step tasks to be carried out for a maintenance activity.

Surveillance procedures

‘Surveillance’ is traditionally referred to as the continual examination of the physical condition and operation of a dam(10) .

Surveillance activities may be documented as part of the dam safety management system document, but are more usually described in the operations and maintenance plan because a large proportion of surveillance activities are routine inspections that are planned and carried out through the maintenance workflow process, or are monitoring processes described in the operational sections of the plan.

The plan should cater for the following surveillance activities:

- planning and scheduling of surveillance activities, procedures and work instructions for routine surveillance tasks and recording requirements

- routine inspections by trained dam personnel as part of their duties at the dam

- more detailed or in-depth inspections of the dam by competent persons as needed (these have traditionally been called intermediate or special inspections and may involve a visual examination of the dam and a review of routine inspection and monitoring data)

- comprehensive inspections – in-depth inspections by competent persons as above, evaluating surveillance data and recommendations by applying current criteria and prevailing knowledge(11)

- monitoring – the collection, presentation and evaluation of data from instrumentation

- evaluation and interpretation of the information gathered through the monitoring and inspections to allow modification of the plan and as input to risk assessment.

Each dam should have surveillance processes tailored to its needs, the scope of which should be appropriate for the size and type of the dam and the dam consequence category. Surveillance should be capable of detecting problems or unsafe conditions at an early stage so that corrective measures can be taken. Experienced dam engineers should be consulted on the nature and extent of surveillance processes for the dam.

Clause 9 (1)(d) - the procedures for reporting incidents in respect of the dam

The dam safety management system document should provide an overview of how the declared dam owner ensures that all dam safety incidents are reported, not just the incidents that are required to be reported to Dams Safety NSW, and the corrective action processes and procedures associated with incidents, in accordance with AS ISO 55001: 2014.

The operations and maintenance plan should include the process and procedure for reporting the incidents that are prescribed in clause 9 (1) (d) to Dams Safety NSW.

The regulator is concerned with those incidents that that could adversely affect safety and security of the dam, its associated structures and critical control systems, and the dam safety management system. Owners are to report safety related incidents and failures to Dams Safety NSW in accordance with the requirements of clause 19 of the regulation.

The purposes of incident or failure reporting are to:

- alert the regulator to a potentially dangerous situation

- provide for the earliest practicable activation of the emergency plan (if necessary)

- enable corrective actions to improve the dam safety management system

- enable Dams Safety NSW to better understand the safety status of the dam.

Safety incidents are to be reported in the categories listed and, in the form specified in clause 19 of the regulation.

a. failure of the dam without release of the dam contents (the dam ceases to perform its functions)

b. failure of the dam, with release of the dam contents, but without a catastrophic breach

c. failure of the dam with loss of the dam contents due to a catastrophic breach

d. any incident or change observed in the dam or its surrounds which could indicate an increased vulnerability to failure (for example, a sudden increase in seepage flow not related to rainfall, appearance of turbidity in seepage flow, appearance of new seeps, appearance of cracking in the dam). This would cause the owner of the dam to become aware of the likely failure of the dam

e. an incident that results in the death or serious injury of a person or that results in significant damage to property or the environment

f. a serious failure or inadequacy in the dam safety management system and associated documentation that could potentially have caused an incident referred to in e)

g. a suspected terrorist attack

h. an incident relating to dam safety that is reasonably likely to cause concern to members of the public

i. any change in the dam or its surrounds that is abnormal and could indicate an increased risk of the failure of the dam. This includes incidents which could interfere with correct functioning of the dam (for example, a landslide into a spillway chute, malfunction of emergency dewatering valves, malfunction of spillway gate operating equipment)

j. breaches of security with implications for dam safety

k. a failure of a control system that had the potential to cause a dam failure.

A procedure(s) should be prepared to ensure that such incidents are identified, documented and reported to Dams Safety NSW(12). It should also cater for the consideration of dam safety incidents in future surveillance inspections, dam safety risk assessments and safety reviews, and address the requirement for corrective action required by the dam safety management system standard.

It is good practice for a dam to have an operations log which provides a chronological record of important events relating to operations, maintenance and dam incidents.

Refer to commentary under clause 9(1)(b) regarding the triggering of alerts relating to the emergency plan. Incidents resulting in activation of the emergency plan are incidents that may need to be reported to Dams Safety NSW in accordance with clause 19 of the regulation.

Clause 9 (1)(e) - the procedures to ensure public safety in respect of the dam during its day to day operation;

The plan must include procedures that address public safety and protection of people attending the dam site (e.g. at viewing areas, community or school tours, picnic and recreation areas, boating, swimming, camping etc). However, it also relates to itinerants visiting, or residents, in areas downstream of the dam that could be affected by surging or rapidly rising changes in water level during controlled flow releases. This sub-clause does not relate to catastrophic failure of the dam and uncontrolled release of contents.

Instructions required by relevant legislation should be included. Unsafe conditions and hazardous areas should be listed.

A general arrangement, or site layout plan, that shows the arrangement of the assets and subassets, components, access points and roads should be included and the type and location of warning signs and other safety features or equipment should be noted.

Areas of the dam restricted to the public should be detailed. The purpose of restriction should be explained. Some examples of restricted areas which are potentially hazardous include:

- confined spaces

- spillway approach areas, chutes and stilling basins

- intake towers and associated access bridges

- control buildings and valve block areas

- unlocked ladders, other forms of access unsuitable for untrained persons

- intake or outlet channels adjacent to hydraulic structures subject to surging or rapid changes in water level during releases

- active landslide areas

- steep abutments and exposed (climbable) faces of dam structures

It is recommended that a risk assessment be carried out to screen and rank potential public safety risks at the dam site and relevant surrounding areas. This should be informed by operational personnel with knowledge of the site and carried out by persons with knowledge of relevant codes and experience in carrying risk assessments of this nature. Consideration of numbers of persons/visitors and their likely exposure is relevant.

Suitable warning and restriction signs should be positioned at appropriate places around the dam and referenced in the plan. The maintenance processes should include security/safety fencing and signage. Regularly review the public safety measures and consider whether any additional public safety measures are feasible and/or necessary.

Warning systems and advance notice of major controlled (gate/valve) releases may need to be provided to cover risk to the community in downstream flood prone areas. This could involve realtime monitoring of discharge and stream gauge levels, electronic control and a communication system.

Reference should be made to a communications directory that includes local law enforcement, medical and fire services.

Clause 9 (1)(f) - the security measures that are in place in respect of the dam.

Security procedures must be documented in the plan so that the risks associated with security breaches at the dam are managed. The following aspects should be considered:

- measures to avoid a failure of a dam with significant consequences for community interests; e.g.:

- to prevent unauthorised heavy vehicle or heavy equipment access to the dam

- to prevent unauthorised persons obtaining as-built drawings of the dam

- measures to avoid unauthorised operation of spillway control systems that would have significant consequences for community interests; e.g.

- to prevent access to on-site spillway gate operating systems

- to prevent access to remote computers controlling spillway gates

Dam owners should give an updated qualitative opinion of the security risk status of their dams in each five-yearly risk assessment report produced in accordance with clauses 14 and 15 of the regulation.

The dam owner may consider including a section in the plan that covers:

- procedures for reporting security information and responding to security incidents

- procedures for recording the outcomes of security surveys and reviews on each dam

- security responsibilities and accountabilities

- procedures for testing/exercising the security measure/procedures

- the identification and location of all relevant documentation including security plans, standards, risk assessments and procedures

Note: For simple dams, these security measures may be relatively simple to match the risks involved.

Further guidance can be found in Standards Australia/Standards New Zealand, Security Risk Management Guidelines, HB167.

Clause 9 (2)(a) - The operations and maintenance plan must set out how the matters in subclause (1) will apply in normal, abnormal and extreme loading operation conditions

Operations and maintenance processes and procedures need to be cover normal, abnormal (unusual) or extreme loading conditions. For example, operating at full supply level with no foreseeable rain events may require a different response to being at full supply level with a 1 in 100- year event predicted in the catchment. All dams are unique in this regard; however, there will be similarities (e.g. generic type responses and alert activations associated with the emergency plan).

The design of a dam requires consideration of these loading categories; e.g. design criteria/industry standards may be applied for full supply level or 1 in 50 Annual Exceedance Probability (AEP) flood (usual), 1 in 2,000 AEP (unusual) and the extreme flood loading case. Additionally, a risk assessment will typically break down the flood failure modes into (at least) these three categories. A piping incident could manifest itself under normal operation, or during a flood or seismic event, thereby triggering intensive surveillance, and potentially an emergency response. Given the differing issues and circumstances, this aspect in the plan will generally require the consideration of a competent person.

A few examples of responses to the differing conditions are shown below:

- normal or emergency operation of spillway gates

- normal operation of water supply control valves versus operation in a flood (valves usually closed)

- more frequent routine inspections and logging of data during a significant or unusual flood event, including monitoring of storage level, inspection of embankment for signs of movement, increased seepage, observation of spillway operation etc.

- re-positioning or storage of trash screens and baulks when flood conditions have been forecasted;

- design flood hydrology and flood routing, reservoir, and spillway operations in normal, unusual, and extreme loading scenarios (needs to be accurate and up to date)

- operations for the purpose of emergency drawdown release (e.g. to prevent a “sunny-day” piping failure due to excessive or concentrated seepage under normal conditions or following a significant flood or earthquake)

- special dam safety inspections (by a competent person) following a major flood, seismic event, or other dam safety incident

- cross-reference to the emergency plan, which includes notifications for different levels of response and trigger levels for initiating alerts

Clause 9 (2)(b) - the operations and maintenance plan must be appropriate to the size and complexity of the dam and its associated structures and systems.

Refer to Section 2.3 of this guideline.

Clause 9 (3) - the operations and maintenance plan may include any other matter that the dam owner considers to be relevant to the operation and maintenance of the dam.

Other items that are should be considered include, but are not be limited to the work, health and safety (WHS) system - dam owners are accountable for ensuring safe systems of work relating to the operation and maintenance of dams (e.g. working in confined spaces, over/under water bodies, working at heights, UV exposure, safe design of ladders and access platforms). The owner’s Health, Safety, Security and Environmental policy/framework could be incorporated in, or referenced from, the plan

Clause 9 (4) - The operations and maintenance plan for a dam categorised as significant consequence, low consequence or very low consequence must be updated at least once every 5 years. Note. Section 16 (3) of the Act requires all other operations and maintenance plans to be updated on an annual basis.

The organisation needs to have a formal review and revision process documented in the plan to ensure the plan is kept up to date. The plan needs to be reviewed and/or revised:

- for extreme and high consequence category dams – at least annually

- for significant, low or very low consequence category dams - at least once every five years.

Key operating personnel/supervisors and related officers should review the plan to ensure all the information is current.

The outcome of a review could simply be to conclude that the plan is still current, requires minor update, or it could be that a complete revision is required.

The above review frequencies should be considered as a minimum, because operations and maintenance activities need to be revised in a timely fashion to capture changes in internal and external operating environment/circumstances. Other changes will also trigger a review of the operation and maintenance plan, for example, contractual, dam configuration, operating levels, installed equipment or changes to organisational structures or the level or nature of external service provision, or identification of new failure modes.

Clause 9 (5) - The owner of a declared dam must, if required by notice in writing to do so by Dams Safety NSW, provide Dams Safety NSW with a copy of the operations and maintenance plan within the time, and in the form, specified in that notice.

Dams Safety NSW may request a copy of the plan in writing, usually as part of the preparation for an audit of the operations and maintenance plan and/or dam safety management system (see section 3.3).

Clause 13(1) The dam safety management system document for a dam must set out the following: (e) - the procedures for ensuring compliance with AS ISO 55001:2014

Roles and responsibilities

The dam safety management system standard (AS ISO 55001:2014) requires that responsibilities and authorities for relevant roles are assigned and communicated within the organisation. This applies to the roles and responsibilities for all operations and maintenance activities (the regulation also requires the plan to identify who is responsible for maintenance activities, including the management and planning of maintenance).

The operating personnel and their responsibilities should be specifically identified, including for regularly scheduled activities they are required to perform.

These responsibilities may be documented in a single section (or table) in the plan or may be documented within the plan’s procedures or work instructions.

Training and competency

The dam safety management system standard requires declared dam owners to ensure that all personnel that affect the safety performance and operation of the dam are competent, based on appropriate education, training, or experience.(13) This is especially important for operations and maintenance staff, who have a direct role in processes that prevent dam failure. In addition, everyone involved in operations and maintenance needs to be trained to identify and report conditions that could lead to dam failure.

Dam operators and maintainers should be aware of the damage potential of the dam and be able to recognise and report deficiencies and adverse trends that could lead to failure.

Owners of declared dams should ensure that:

- there are appropriately trained and experienced personnel available to operate and maintain their dams in accordance with their operations and maintenance plans

- training plans are in place for staff and staff meet the required levels of competency

- processes are in place to identify the level of competency required and to carry out and record the training.

Some roles or functions may be carried out by external service providers and the organisation should have appropriate processes for assuring their competence and assuring or managing their activities.

4. Plan form and contents

An operation and maintenance plan is unique to a particular dam, as no two dams are the same (although there will be similarities). The plans for different dams are unique for many reasons/factors: location, operating entity, purpose, operating equipment, size, design, appurtenant structures, spillway type (gated/ungated) saddle dams, instrumentation, etc.. As stated previously, the plan should be tailored to the type, size and complexity of the dam.

There are too many combinations of features and equipment at dams to be able to cater for all of them in this guideline. The author(s) of a plan should use their best judgment when organising the contents in each section. This applies mostly to the sections of the plan covering the operation and maintenance of structural and mechanical and electrical equipment and dam, spillway and reservoir operations.

The format of the plan may follow a standardised format such as the outline suggested in Appendix A of ANCOLD (2003a) or USBR (2012), with additions specific to the regulatory requirements. The contents can be adapted to suit the characteristics of the dam, supporting information and other requirements of the dam owner. Also, a dam owner may develop and implement a single plan or a set of documents that achieve the same purpose. Some dam owners may have an integrated maintenance system that embodies many of the procedures required by an ‘operations and maintenance plan’. A reference to the system is an appropriate way to document those sections of the plan.

Major dams that include high capacity spillway gates, multifaceted spillways and convoluted outlet works can be highly complex structures. Owners of these types of dams should already have a detailed operation and maintenance manual in place, with well-established layouts and contents; this guideline provides guidance on additional things to consider when updating these manuals.

As stated in section 2.3, a plan for a simple dam structure with a low consequence category may be a comparatively simple document.

The following section headings are suggested headings(14) and should be adapted, simplified or deleted as appropriate to the dam type, characteristics and complexity:

- Preliminary Pages – table of contents, revision sheet, authorisation signatories, other document control details, cross reference to emergency plan (notifications and communications), glossary and abbreviations

- Section 1, ‘General’ – background, dam description and data, safety management system references, responsibilities, attendance, communication and warning systems, training and competence, information management, supporting information: emergency plan, data reporting and operations log, risk management framework, design report, drawings, dambreak and consequence category assessment, design operating criteria, geology, seismic and hydrology studies, public safety procedures, health and safety

- Section 2 ‘Risk Framework input to the plan’ – a summary of the risk analysis that provides information for the development and implementation of the operations and maintenance activities/processes; describe how the five-yearly risk report should lead to a review of the operations and maintenance plan

- Section 3, ‘Dam, Spillway and Reservoir Operations’ – data on design flood hydrology and flood routing, operating procedures, reservoir/spillway operations in normal, unusual and extreme loading scenarios, environmental and riparian releases, emergency dewatering

- Section 4, ‘Civil/Structural, Mechanical and Electrical’ – work management system (maintenance planning, maintenance schedule, work assignment and recording system), information and instructions for safe operation, maintenance of dam and appurtenant civil structures, and maintenance of mechanical and electrical equipment, pipework, structural steelwork, metalwork and access structures typically associated with appurtenant structures (outlet works and spillways)

- Section 5, ‘Surveillance’ – monitoring, routine inspections by dam operator, special and comprehensive inspections

- Section 6, Incident management and incident reporting

- Section 7, ‘Review of Operations and Maintenance Plan – the process or procedure for review of the plan.

Section 1 of the plan should contain information and instructions concerning the administration of the dam. All plans should include this. Section 1 should also outline the supporting documentation including the related elements of the dam safety management system documentation.

Section 2 of the plan should include a description of how the dam safety management system risk assessment process informs operations and maintenance planning.

Section 3 should include procedures for the maintenance planning and scheduling system and the work assignment system used to manage maintenance (and surveillance) activities. Sections 3 and 4 of the plan should be tailored to meet the requirements of the structures and equipment installed at the dam and the dam and spillway operations. Even simple dams (e.g. retarding basins) may incorporate static metalwork items and access structures that are critical to operations and require maintenance.

Normally, industry precedent (good) practice is applied in addressing how to operate, test, maintain and overhaul critical flow control and other important mechanical and electrical equipment and instrumentation for the dam and its associated structures; i.e. including the consideration of maintenance intervals.

Section 5 should include the surveillance activities for the dam.

Section 6 should include the incident recording and reporting procedures for the dam, including procedures for reporting incidents to Dams Safety NSW.

Section 7 describes the processes for regular review of the plan.

Further information on the form and contents of a plan can be found in the list of resources listed in Section 5 below.

| Reference | Description | Usage |

|---|---|---|

| ANCOLD (2003a) | Australian National Committee on Large Dams (ANCOLD), Guidelines on Dam Safety Management, August 2003 | Australian dams industry guideline that provides information on the suggested form and contents of operations and maintenance manuals and related elements of dam safety management programs - management and accountability; overview of investigation, design, construction and commissioning; surveillance; safety reviews; remedial action; and emergency planning. |

| ANCOLD (2003b) | Australian National Committee on Large Dams (ANCOLD), Guidelines on Risk Assessment, October 2003 | Australian dams industry guideline that provides technical information on undertaking risk assessment for dams, including types and levels of risk assessment, failure modes analysis, estimation of likelihood, consequences and risks, tolerability of risk, assessment of risk reduction options. |

| DNRM (2002) | Department of natural Resources and Mines (DNRM), Queensland Dams Safety Management Guidelines, 2002 | Queensland regulatory guideline on dam safety. Includes a section on operations and maintenance – objectives, key standing operating procedures, level of attendance, detailed operations and maintenance manuals and recording and work assignment system. Provides extensive information relating to dam surveillance (monitoring, inspections and evaluation) and managing a dam safety program. https://www.dews.qld.gov.au/__data/assets/pdf_file/0007/78838/qnr m02013.pdf |

| FERC (website) | United States Federal Energy Regulatory Commission (FERC), Dam Safety and Inspections | Engineering Guidelines; various chapters at the following link: e.g. Chapter 14, “Dam Safety Performance Monitoring Program”, describes how to undertake Failure Modes Analysis, surveillance and monitoring procedures and guidelines etc. A search of the “Dam Safety and Inspections” area will reveal other useful information if/as required – generally for use of dams engineering specialist. |

| USBR (2015) | United States Bureau of Reclamation (USBR) Directives and Standards, FAC TRMR-66, temporary release (expires 14/5/2021) | Document issued to ensure operating practices and procedures are uniformly applied for USBR High and Significant Hazard dams. Establishes minimum requirements for certain operations-related activities. Topics include Standing Operating Procedures (SOPs); dam operating training; operating logbooks; gate exercising and testing; and related safety and security procedures. |

| USBR (2012) | United States Bureau of Reclamation (USBR) Water Operation and Maintenance Bulletin No. 231 – Development of Standing Operating Procedures for Dams; and Maintenance and Maintenance Management Practices | Provides guidance on developing the contents of ‘Standing Operating Procedures’ (SOPs) for high and significant hazard dams owned by USBR. In this context SOPs considered similar to contents of an operations and maintenance plan. |

| India Gov CWC (2018) | Government of India, Central Water Commission, Central Dam Safety Organization, Guidelines for Preparing Operation and Maintenance Manual for Dams, Doc No. CDSO_GUD_DS_03_v 1.0, January 2018. | Detailed guidance on preparing an operations and maintenance manual in a similar vein to US and Australian industry practice. Suggested contents outline differs but includes similar elements. https://damsafety.in/ecmincludes/PDFs/Guidelines_for_Preparing_O&M_Manuals_for _Dams.pdf |

| State of Victoria, Australia | Victorian Department of Environment, Land, Water and Planning: ‘Your Dams Your Responsibility’ sections 6 and 7 on surveillance and operations and maintenance | Guidance on surveillance, operations and maintenance https://www.water.vic.gov.au/__data/assets/pdf_file/0017/54251/You r-dam-Your-Responsibility-2018-05-19-digital-version-.pdf |

Appendix 1 The dam safety management system risk framework and operations and maintenance plans

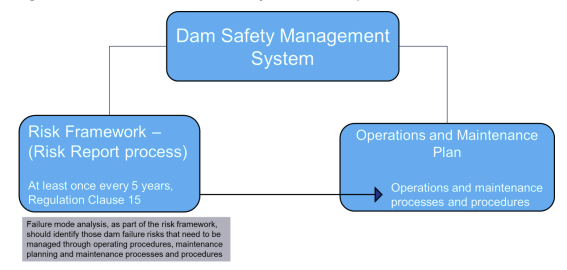

The risk management framework is documented in the dam safety management document. The following describes how the risk management framework process informs the development and implementation of the operations and maintenance plan.

A dam safety management system needs to be established and implemented by the owner as the primary means of ensuring that risks to public safety and to environmental and economic assets from dam failure are managed throughout the life cycle of the dam, including the design, construction, operation and maintenance and decommissioning of the dam(15).

A key aspect of the regulation is the risk framework that is to be established as part of the dam safety management system (clause 14 of the regulation). As well as other risks that need to be addressed through the application of the risk framework, application of the framework will identify those dam failure risks that are addressed through the implementation of the operations and maintenance plan.

The plan is therefore informed by the dam safety risk framework and risk assessment process; i.e. in terms of developing, reviewing and updating operating and maintenance procedures which deal with potential failure modes through operating processes, maintenance, and monitoring and surveillance processes.

Clause 15 of the regulation requires that the clause 14 risk management framework is used to produce a quantitative risk assessment report on the dam every five years. It is recommended that the operations and maintenance plan is also reviewed after the risk assessment process to adjust operating procedures, maintenance (and surveillance) tasks to address the updated risk findings.

Figure 2 depicts the relationship between the safety management system elements related to operations and maintenance.

A plan for a new dam should be developed at the design stage, with regard to the risk assessment and design criteria developed for the dam.

The as-constructed configuration of a dam may vary from the assumptions used at the time of the design, and analyses and risks can change over time (such as with deterioration of asset condition). This requires the application of the risk framework to be an on-going process – not just a one-off exercise – and a risk analysis should be undertaken to augment the original analyses when preparing the plan.

Applying the risk management framework to operations and maintenance

General

Clauses 14(2) of the regulation states that the risk management framework components must include:

- a) a hazard identification process;

- b) a risk analysis process;

- c) a risk evaluation process;

- d) a risk treatment process.

and clause 14 (4) states:

(4) The risk analysis process must employ an evidence based quantitative methodology that identifies and analyses the following:

- a) the potential failure modes of the various parts of a system in its operating context

- b) the effects those potential failures may have on the system

- c) how to avoid those potential failures

- d) how to mitigate the effects of those potential failures on the system.

According to clause 14 (4), failure mode analysis is part of the risk management framework. This analysis is carried out:

- as part of the dam safety risk assessment report, at least once every 5 years

- if a major change is proposed to be made to the dam, at the time that the change is being designed that takes into account the proposed change and

- as part of a safety review.

The analysis needs to consider failure modes that are wide in scope to cover all of the potential dam failure modes for the risk report, but those potential dam failure modes that are relevant to operating and maintenance should be considered when developing or reviewing the plan. Conversely, operations and maintenance activities, and especially dam surveillance activities, should inform the risk framework process. This is to ensure that problems or unsafe conditions are detected at an early stage so that preventive or corrective measures can be undertaken.

Failure modes analysis (FMA)

FMA is encompassed in the hazard identification and risk analysis processes (regulation clause 14(a) and (b)) and is used to inform the risk evaluation and risk treatment processes.

FMA identifies the ways in which failure of the dam could conceivably occur and then selects, for further assessment, those modes which are credible. An FMA will define the dam system and the major elements in the dam that are critical to dam safety; e.g. main dam structure, saddle dams/fuse plugs, spillway structures (e.g. chute slabs, dissipator) and spillway and outlet works critical flow control elements (gates, conduits etc.).

The analysis should allow for differences in the failure modes of structural versus control elements. For example, spillway control systems have a higher probability of failure, but less consequence as compared to the dam structural failure that has a lower probability of failure but potentially a significantly large consequence.

An FMA will identify physical issues and vulnerabilities which may require attention as part of routine surveillance (e.g. checking for signs of excessive seepage around an outlet conduit). It could also lead to a recommendation to increase the frequency of inspections, modify surveillance procedures, or to install monitoring instrumentation (e.g. piezometers).

Some examples of operational-related issues that could be influenced or informed by an FMA process include:

- operating procedural adjustments (e.g. temporary lowering of normal operating level)

- procedural issues (e.g. setting of normal operating criteria)

- critical operating procedures (e.g. discharge control and flood release protocols including monitoring and warning of areas of impact prior to release)

- emergency action and incident reporting

- tailoring of routine inspection tasks and focus areas

- triggering a special inspection (e.g. by a dam safety/design engineer, mechanical and engineer, diving inspection of underwater structure)

- modifications to monitoring procedures or instrumentation

- other preventive maintenance improvements or increased frequencies

- non-maintenance solutions (e.g. equipment re-designs)

The review of failure modes for a dam typically may involve a workshop with attendees comprising engineers involved in preparing the risk assessment, dam owner’s engineers, dam operations and maintenance staff, and possibly other participants with diverse backgrounds. The workshop would develop a common understanding and consensus of the potential failure modes and potential vulnerabilities, so they are not missed and are catered for in the risk assessment and subsequent review of the plan.

For relatively simple dams such as retarding basins the principles behind the techniques can be applied in a way that suits the lower complexity of the dam. While specialist input is recommended for the analysis, Appendix 2 includes an example that illustrates one way to address the documentation for a basic analysis for a retarding basin.

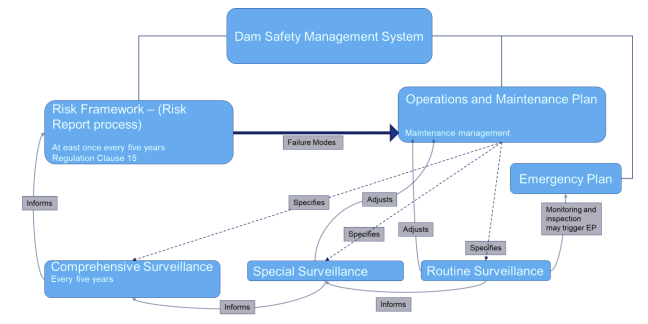

How surveillance activities relate to the FMA process and review of the plan(s)

Surveillance activities provide information to the dam owner of the condition of the dam to enable an appropriate response. The response could be an alarm trigger, or could be an adjustment to the operating, maintenance or surveillance activities.

It is recommended that a comprehensive inspection (five-yearly) is carried out to provide an input to the risk assessment report required by the regulation (required at least every five years). A comprehensive inspection could be carried out by a team to facilitate a subsequent failure modes workshop, and a review of the operation and maintenance plan following the workshop.

Figure 3 describes how surveillance activities relate to the FMA and review of the dam plans.

Footnotes

(1) The operations and maintenance plan for a declared dam is referred to throughout this guideline as ‘the plan’.

(2) Australian National Committee on Large Dams https://www.ancold.org.au/.

(3) The emergency plan is the principal document the deals with the dam’s emergency response. The operations and maintenance plan should reference the emergency information within the emergency plan.

(4) competent person is defined under clause 3 of the regulation.

(5) A competent person is defined under clause 3 of the regulation.

(6) Relevant specialty is also defined in clause 3 of the regulation.

(7) Refer to ‘surveillance procedures’ in clause 9 (1)(c) of section 3.3 of this guideline.

(8) A safety review is defined and requirements for such in section 20 of the regulation.

(9) Some references, for example DNRM (2002), refer to these as ‘standing operating procedures’.

(10) AS ISO 55001:2014 refers to these activities as: ‘Monitoring, measurement, analysis and evaluation’.

(11) The former regulator (NSW Dams Safety Committee) required comprehensive surveillance inspection reports to be submitted for review every five years. Surveillance inspection reports are not required to be sent to Dams Safety NSW. However, the need for this inspection should be considered by the dam owner as an important part of their risk management process for the dam.

(12) The Dams Safety NSW website has an incident reporting form for dam owners to use to report incidents.

(13) AS ISO 55001:2014 section 7.2 ‘competence’.

(14) Noting that dam owners may adopt any other format if it suits their needs and organisation’s structure

(15) A declared dam owner must establish and implement a dam safety management system by 1 November 2021

(16) Specialist input from a competent person is recommended for the analysis

(17) The ‘Neverfail’ basin is assumed to be dry most of the time and to have a grassed embankment (as opposed to rock or concrete)